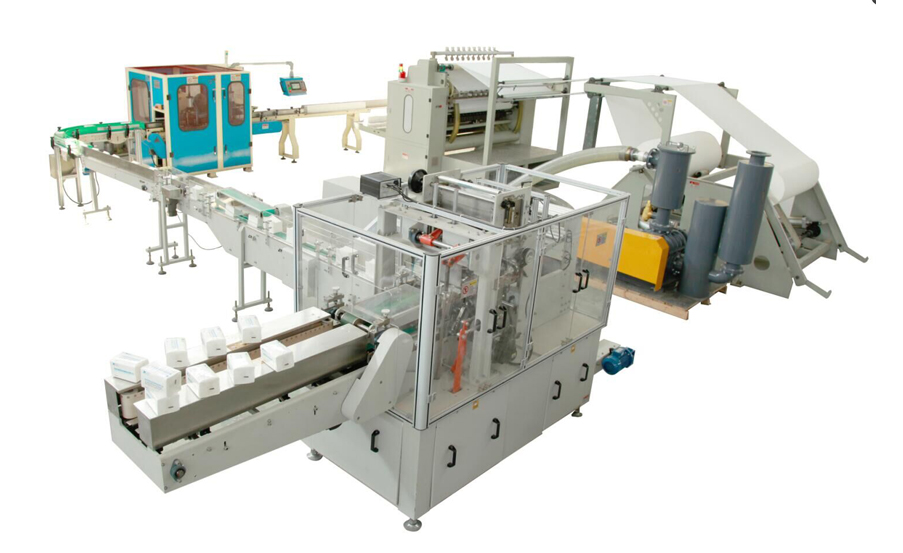

Automatic Box Drawing Facial Tissue Production Line

Application:

Automatic facial tissue production line is consist of facial tissue folding machine, single channel log saw, single bag packing machine. Machine working smoothly and stable from the raw material to finished products. This production line is of high degree of automation, save labor costs, reduce labor intensity, is the best choice of the production of tissue products.

Approx Ex-work Price:

US $7000~$29000

HX-CS190/7L facial tissue making machine

Working flow :The jumbo rolls which have been slit into the desired width are cut by the slitting cylinders,and then interfolded into interoverlapped rectangular facial tissue sheets.This machine adopts independent servo motor drive ,and automatic paper tension control. It features of high speed ,nice folding and easy operation .

Can order steel to rubber embossing rolls,pneumatically separated.

Wallboard rack and Machine running stability and extremely good and fast.

Pneumatic jumbo roll loading,pneumatic paper driving ,stepless speed additionustment ,and web tension control.

Equipped with roots type vacuum pump for stable running of the machine

Make various products width as requirement .

Equipped with edge embossing unit to keep the two plies together.

The machine will stop when the paper broken.It avoid waste caused by no paper or paper broken.

The web can be threaded on the machine by the two jog buttons,It’s more safety and easier to thread the web.

HX-DHX-150 Single Channel large roundabout slitter

Cyclotron paper cutter is used to automatically cut off a row folded and round roll paper towel products, such as the removable tissue or toilet roll paper. The whole machine adopts servo drive technology and frequency control of motor speed and enhance the stability of paper cutting, and improves the cutting precision of tissue and to cut off the end face flat . Cutting length within the scope of the machine allows arbitrary adjustable. Fixed automatic knife grinding wheel Angle, ensure the quality of the sharpening knife. Knife grinding place often blow compressed air for cooling, and can match the special cooling fluid.

Model HX-CS190/7L Box Drawing Facial Tissue Machine Technical Parameter

| Machine model | HX-CS-190/7Lmm |

| Finished products unfolded size | 95X(120-210)±2mm |

| Folding products size | 190X210±2mm |

| Raw material width | 1400mm |

| Raw material diameter | 1100mm |

| Raw material core diameter | 76.2mm |

| Out put (8 hours) | 2000-3000Kg |

| Embossing unit | Steel to steel, Steel to steel edge embossing ,independent pneumatic regulation |

| Slitting unit | Pneumatic slitting |

| Power | 5.5KW Main motor |

| 1.5KW(2set) Unwind motor | |

| Vacuum suction unit | 18.5KW Fan |

| Pneumatic system | 3 HP air compressor ,mini pressure 5kg/cm2PA |

| Driving system | Timing belt |

| Dimension | 7950X2500X1850mm |

| Weight | 6.0T |

HX-DHX-150 Single Channel large roundabout slitter Main technical parameters

| Designation | Parameter values |

| The length of the none cut off facial tissue | minimum 500mm |

| The Height of tissue | 30~130mm |

| Machine Speed | 20~150cut/min |

| operating speed | 20~120cut/min |

| Round blade outer diameter | Φ610mm |

| Paper cutting circular knife top speed | 980R/min |

| Finished products specification | 70~300mm |

| Paper width | 70~110mm |

| Cutting Length | 70~300mm |

| Left-over Length | 20~65mm |

| Power | 11KW |

| power supply | 380V 50Hz |

| Air source | 0.5~0.8MPa |

| Machine Size | 4600*1700*2500mm |

| weight of machine | 2300~2600kg |

| brake | Parameter setting (auto/manual) |

| Stepping sharpening knife | Parameter setting (auto) |

| Pneumatic sharpening knife | Parameter setting (auto/manual) |

| Blow air | without |

| The total pressure switch | Value (not) |

| human-computer interface | Optional Matching (Standard Desk DelTA) |

| frequency changer | DELTA |

| Servo Drive | DELTA |

HX-T80SD Automatic Facial Tissue Packing Machine Main technical parameters

| Technical Specifications | Description | Remark |

| Scope of application | Facial tissue, hand towel,napkin tissue | |

| Infeed | ASF Full automatic | Five sections of intelligent flexible feeding mode |

| Max.design mechanical speed | ≤ 80 bags/min | Related to specification of packing |

| Max. stable operation speed | 65 bags/min | Related to specification of packing |

| Tissue length range (finished product) | 120 mm- 210 mm | Over this size can be customized |

| Tissue height range(finished product) | 40 mm- 100 mm | |

| Tissue width range(finished product) | 90 mm- 105 mm | |

Spare parts for change size | 3 set | Standard configuration quantity, the accurate specifications drawn up by the user |

Machine size | Length 4600 mm Width 3620 mm Height 1770 mm | Standard size |

| Machine weight | About 3000 KG | |

Packing raw material | CPP film | |

| Film Thickness | 0.04mm-0.055mm | |

| Max film diameter | 400 mm | Over this size can be customized |

| Film core diameter | 76mm | In accordance with international standards |

| Max film width | 340mm | Over this size can be customized |

| Air pressure | Minimum air pressure 5MPA | Equipped by user |

| Power supply | 380V/50HZ | Following China’s electric power standard |

| Total drive power | 4.8 KW | The sum of main motor, servo motor, Sum of speed regulating motor power |

| Total heating power | 4.6 KW | Side seal, side sealing part of heating power combined |

| Voltage variation | +/-10% | In accordance with international standards |

| I/O Input/ I/O | 24VDC | Electrical control system control circuit input |

| I/O Output/ I/O | 24VDC | Electrical control system control circuit output |

| Machine run control pattern | Three axle servo and axle location control | The electronic CAM motion curve |

| Equipment main transmission mode | 20crmnti mechanical-cam+The electronic CAM drive | |

| Machine standard colour | Gray, International color RAL 7032 | The international color card color number RAL7032 |

| Packing format | Three-dimensional wrap | vertical sealing first and then two side sealing |