Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Application:

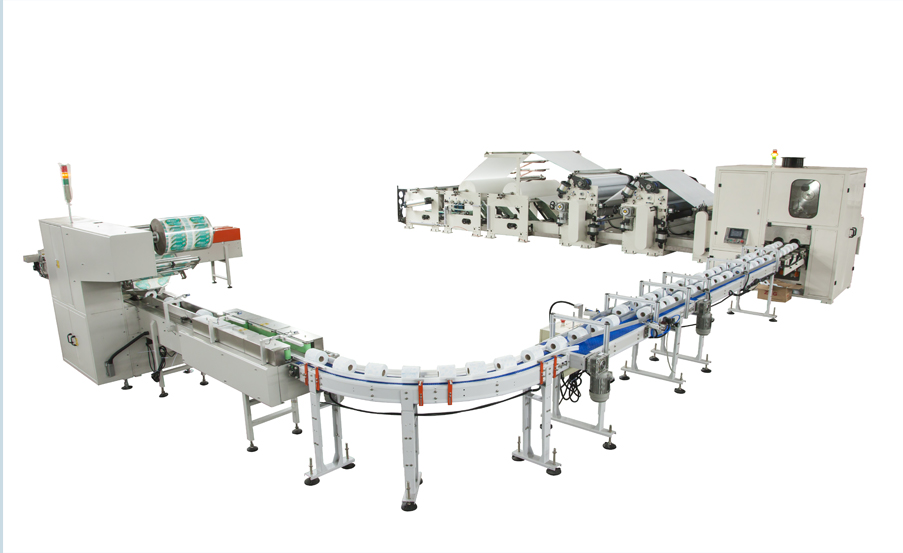

This production line consists of Fully Automatic Rewinding Machine/Color Glue Lamination.Log Saw Machine and Automatic Single Rolls Packing Machine. It converts the jumbo roll into the finished kitchen paper rolls or toilet paper rolls. The whole line work smoothly and run stable, saving the labor cost and reducing the labor strength, it’s best choice for the producing hygienic paper products.

Full automatic wallboard type color glue lamination kitchen towel/toilet paper rewinding machine

| Model | HX-SJD-1575 Full automatic wallboard type color glue lamination kitchen towel/toilet paper rewinding machine |

| Jumbo Roll Max Width | 1750mm (Other size can be specified) |

| Jumbo Roll Diameter | Φ1100mm(Other size can be specified) |

| Jumbo Roll Inner Diameter | 3inches(76.2mm) (Other size can be specified) |

| Perforation Distance | 4 anvil Blades(115mm)(Other size can be specified) |

| Finished Product Diameter | Φ80~φ140mm |

| Finished Product Core Diameter | φ38~φ76mm |

| Production Speed | 0~230m/min |

| Program Controller | PLC(Delta) |

| Unwind Stands | 1 or 3 Stands(Need to be specified) |

| Pneumatic System | 3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user) |

| Main Power | 15KW |

| Dimension | 10000*2900*2000(L*W*H) |

| Weight | 10T |

| Jumbo Roll Layers | 1~3 layers,14~30gsm kitche paper or toliet paper |

| Edge-Line Embossing(can be specified) | Steel to steel (Pneumatic Control) |

| Embossment (can be specified) | Double Sets embossing unit steel to rubber(the embossing unit can be order individually) |

| Voltage | 380V 50HZ |

Log Saw Functions And Features

HX-DHX-150 Double Channel Log Saw Machine is used for cutting the toilet paper roller and kitchen towel paper roller, it’s with high automation and efficient. Adopts advanced servo driving system, frequency conversion speed regulating, PLC control and touching screen operation.

Log Saw Technical Parameter

| Model | HX-DHX-150 Log Saw Machine(Double Channel) |

| Jumbo Roll Max Width | 1750mm (Other size can be specified) |

| Jumbo Roll Diameter | Φ105~φ115mm(Other size can be specified) |

| Design Speed | 150Cuts/min |

| Stable Speed | 100Cuts/min |

| Grinding System | Pneumatic Sharpen, grinding time can be set |

| Driving System | Delta /Mitsubishi Servo Motor |

| Power | 11KW |

| Dimension | 6500*2500*2000mm(Other size depends on model and configuration) |

| Blade Diameter | φ610*4.7(mm) |

| Voltage | 380V 50HZ |

| Weight | About 4.5T |

Automatic Single Toilet Roll Packing Machine Features:

HX-R200SD Automatic single toilet roll packing machine features adopt to kitchen towel and toilet paper with core and without core package.

Toilet rolls feeding,put the packing film,,vertical sealing,coreless rolls air exhaust,reversing all action control by sever motor,have completely all function , high efficiency, simple operation, specifications to adapt to a wide range, the quick changeover specifications, the advantages of convenient maintenance and low use cost.

Stable speed with core the maximum speed is 200rolls/min

Stable speed without core the maximum speed is 150rolls/min

It is adjustable the tissue length from 80mm-195mmonly set by electronic.

Automatic Single Toilet Roll Packing Machine Technical Parameter:

| Model | TP-R200SD | |

| Packing speed(roll/min) | 20-200rolls/min | |

| Maximum production speed(roll/min) | 200rolls/min | |

| Film roller maxi width(mm) | 430mm | |

| Tissue specification | Length(mm) | 80-195 |

| Diameter(mm) | 80-125 | |

| Total power | 12 KW | |

| Motor Power | 3.2KW | |

| Cutting blade | double blade | |

| Packing film structure | Double roller | |

| Machine net weight | 1800KG | |

| Equipment noise (db) | ≤78DB | |

| Production rate | ≥97% | |

| Machine size(LXWXH) | 5500×3300×1600 | |

| Voltage | 220V 50HZ | |

| Raw material of film | BOPP、SPP、CPP | |

| Film Thickness (mm) | 0.018-0.03 |