Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

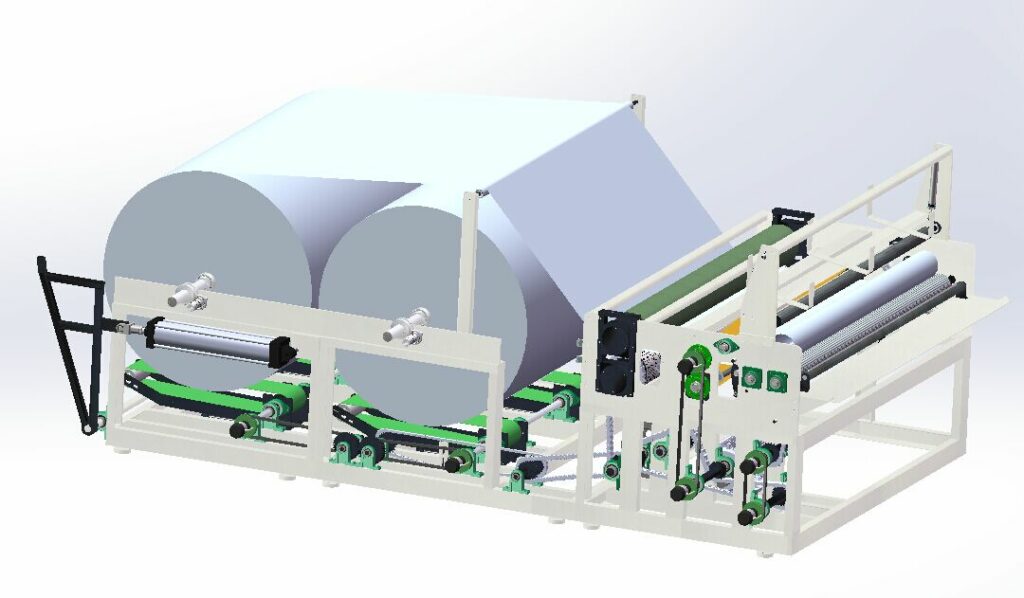

Application:

Semi-automatic rewinding machine, for toilet paper roll making. This machine is for toilet paper roll processing. Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

Function and Features:

1. Automatic core feeding system, automatic log pusher after rewinding, then rewinding the new log again.

2. Automatic edge-trimming, core feeding, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

3. Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

4. Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

5. Three horizontal type back stands, pneumatic loading system, with wide driving flat belts; each jumbo roll can be adjusted independently.

6. Embossment Unit: adopt point to point embossing rollers, making the two layers match well, the paper is soft and has clear patterns

7. Adopt jogging switches for wearing the paper, easy and safe to operate.

| The width of jumbo roll | 1200-2800 mm |

| The diameter of jumbo roll | 1200 mm(Other size can be specified) |

| Jumbo roll inner core diameter | 3inches(76.2mm) |

| Finish product diameter | Φ70-φ280mm |

| Finish product Inner core diameter | φ38-φ76mm |

| Perforation distance | 4 anvil Blades 90-150mm;2 anvil Blades 180-300mm |

| Speed | 180-230 m/min |

| Embossing device | Steel to rubber |

| Pneumatic system | 3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user) |

| Rewinding Unit | With core or coreless |

Kasko yaptırırken bazı sigorta şirketlerinin araç kamerası olan araçlara indirim uyguladığını duymuştum. Bu konunun doğruluğunu araştırıp ona göre bir bursa araç kamerası yatırımı yapacağım. Hem güvenliğimizi hem bütçemizi korur.

Benzer bir ürün kullanıyorum ve kesinlikle herkese tavsiye ederim. Özellikle Organize Sanayi Bölgesi trafiğinde sabah ve akşam saatlerinde çok faydasını gördüm. İyi bir bursa araç kamerası gerçekten hayat kurtarabilir.

Geçen ay küçük bir kazaya karıştım ve haklı olmama rağmen ispatlamakta zorlandım. O günden sonra hemen bir bursa araç kamerası araştırmaya başladım. Keşke bu olayı yaşamadan önce bu yazıyı okuyup önlemimi alsaydım.

Daha önce araç kamerası kullanma konusunda tereddütlerim vardı, gereksiz bir masraf gibi geliyordu. Ancak trafikte yaşananları gördükçe bir bursa araç kamerası taktırmanın lüks değil, ihtiyaç olduğunu anladım. Verdiğiniz bilgiler için teşekkürler.

Daha önce araç kamerası kullanma konusunda tereddütlerim vardı, gereksiz bir masraf gibi geliyordu. Ancak trafikte yaşananları gördükçe bir bursa araç kamerası taktırmanın lüks değil, ihtiyaç olduğunu anladım. Verdiğiniz bilgiler için teşekkürler.

Daha önce araç kamerası kullanma konusunda tereddütlerim vardı, gereksiz bir masraf gibi geliyordu. Ancak trafikte yaşananları gördükçe bir bursa araç kamerası taktırmanın lüks değil, ihtiyaç olduğunu anladım. Verdiğiniz bilgiler için teşekkürler.

Harika bir yazı olmuş, teşekkürler. Özellikle Bursa’nın yoğun trafiğinde neyle karşılaşacağımız belli olmuyor. Olası bir durumda elimde kanıt olması için kaliteli bir bursa araç kamerası almayı düşünüyorum. Bu yazı karar vermemde çok yardımcı oldu.

Bu yazıyı okuyana kadar araç kameralarının bu kadar çok farklı özelliği olduğunu bilmiyordum. GPS takibi yapabilen bir bursa araç kamerası özellikle uzun yola çıkanlar veya aracını başkasına emanet edenler için büyük kolaylık.

Bursa gibi büyük ve hareketli bir şehirde araç kullanmak ekstra dikkat gerektiriyor. Bir bursa araç kamerası kullanarak sadece kendimizi değil, trafikteki diğer masum sürücüleri de korumuş oluruz. Kesinlikle her araçta olması gereken bir cihaz.

Teknolojiyle aram pek iyi değil, bu yüzden kullanımı basit bir cihaz arıyorum. Tak-çalıştır şeklinde, karmaşık ayarları olmayan bir bursa araç kamerası benim için en ideali olacaktır. Bu konuda bir öneriniz var mı?

Bu makale, bir bursa araç kamerası satın almadan önce nelere dikkat etmem gerektiğini net bir şekilde özetlemiş. Özellikle çözünürlük ve lens açısının önemini şimdi daha iyi anlıyorum. Emeğiniz için teşekkürler.

Geçen ay küçük bir kazaya karıştım ve haklı olmama rağmen ispatlamakta zorlandım. O günden sonra hemen bir bursa araç kamerası araştırmaya başladım. Keşke bu olayı yaşamadan önce bu yazıyı okuyup önlemimi alsaydım.

Aracımı genelde AVM otoparklarına veya cadde üzerine bırakıyorum. Döndüğümde küçük çiziklerle karşılaşmak can sıkıcı oluyor. Sanırım park modunda hassasiyeti yüksek bir bursa araç kamerası bu soruna çözüm olabilir.

Selamlar, biz Bursa’da düğün, nişan ve kurumsal etkinlikler düzenleyen bir firmayız. Yaptığımız işleri Instagram’da paylaşıyoruz ama web sitemiz biraz atıl kalmıştı. “Bursa düğün organizasyon firmaları” aramasında görünür olmak istiyoruz. Aklıma şöyle bir fikir geldi: Sitemizin blogunda “Bursa’daki En İyi 10 Kır Düğünü Mekanı”, “Şirket Lansmanı İçin Organizasyon Fikirleri” gibi listeler ve rehberler yayınlayabiliriz. Bu içerikler hem evlenecek çiftlerin hem de şirketlerin ilgisini çekecektir. Bursa SEO sadece teknik bir iş değil, aynı zamanda yaratıcılık da gerektiriyormuş.

İyi günler. Yıllardır Bursa’da sigorta acenteliği yapıyorum. Bizim işimiz tamamen güven ve birebir ilişki üzerine kuruludur. İnternet bize çok uzak bir dünyaydı. Ancak yeni neslin artık sigorta acentesini bile internetten aradığını görüyorum. “Bursa en uygun trafik sigortası” veya “tamamlayıcı sağlık sigortası tavsiyesi” gibi aramalarda neden ben çıkmayayım? Siteme sigortacılıkla ilgili temel bilgileri, hasar anında yapılması gerekenleri anlatan bir bölüm eklemeyi düşünüyorum. Bu bursa seo çalışmaları, geleneksel iş kollarının bile dijitalleşmek zorunda olduğunun bir kanıtı.

İyi günler, Bursa’da bir sürücü kursumuz var. Rekabet o kadar arttı ki, fiyat kırmaktan başka bir şey yapamıyoruz. Artık farklı bir yol denemeye karar verdim. Web sitemizin blogunda “Bursa’da direksiyon sınavı güzergahları ve ipuçları”, “Elektronik sınavda en çok çıkan sorular”, “Sıfırdan araba kullanmayı öğrenme rehberi” gibi içerikler üreteceğiz. Bu sayede sadece kurs arayanları değil, ehliyet süreciyle ilgili bilgi arayan tüm adayları sitemize çekebiliriz. Bu içerik odaklı Bursa SEO stratejisi, bizi sadece fiyatla rekabet etmekten kurtaracak.

Selam ustalar, abiler. Biz baba mesleği mobilya döşeme ve tamiri işi yapıyoruz. Eskiden herkes birbirini tanırdı, işler tavsiyeyle gelirdi. Şimdi insanlar koltuğu yırtılınca bile internete “Bursa koltuk döşeme fiyatları” yazıyor. Biz de bir web sitesi yaptırdık ama pek bir faydasını görmedik. Sanırım bizim de yaptığımız işlerin öncesi-sonrası fotoğraflarını koymamız, “Kadife koltuk nasıl temizlenir?” gibi pratik bilgiler vermemiz gerekiyor. Bu bursa seo işini öğrenip, dededen kalma mesleği internete taşımak şart oldu.

Değerli arkadaşlar, ben Bursa’da faaliyet gösteren bir yeminli mali müşavirim. Bizim mesleğimizde reklam yapmak yasak ve etik değil. Ancak mükellefleri ve potansiyel mükellefleri bilgilendirmek serbest. Web sitemi bu amaçla kullanıyorum. “Yeni Şirket Kuruluşu ve Vergi Süreçleri”, “Bursa’daki KOSGEB Destekleri”, “e-Fatura’ya Geçiş Rehberi” gibi konularda makaleler yayınlıyorum. Bu sayede uzmanlığımı ortaya koyarken, internette araştırma yapan bir şirket sahibinin bana ulaşmasını sağlayabiliyorum. Bursa SEO, bizim gibi meslekler için en doğru dijital pazarlama yöntemidir.

Selamlar, biz Bursa’daki organize sanayi bölgelerinde fabrika ve üretim tesisi temizliği hizmeti veriyoruz. Bizim müşteri kitlemiz son kullanıcı değil, direkt fabrika müdürleri veya satınalma sorumluları. Bu yüzden Instagram, Facebook gibi yerler bize pek müşteri getirmiyor. Web sitemiz var ama aramalarda nasıl çıkacağımızı bir türlü çözemedik. “Bursa endüstriyel temizlik” yazdığında rakipler çıkıyor. Sanırım bizim de “Gıda Üretim Tesislerinde Hijyen Standartları” veya “Otomotiv Fabrikalarında Zemin Temizliği Nasıl Yapılır?” gibi daha profesyonel ve teknik içerikler üretmemiz gerekiyor. Bu bursa seo olayı, B2B (firmadan firmaya) çalışanlar için daha farklı dinamiklere sahip sanırım. Bu konuda tecrübesi olanlardan tavsiye alabilirim.

Selamlar, biz Bursa’da düğün, nişan ve kurumsal etkinlikler düzenleyen bir firmayız. Yaptığımız işleri Instagram’da paylaşıyoruz ama web sitemiz biraz atıl kalmıştı. “Bursa düğün organizasyon firmaları” aramasında görünür olmak istiyoruz. Aklıma şöyle bir fikir geldi: Sitemizin blogunda “Bursa’daki En İyi 10 Kır Düğünü Mekanı”, “Şirket Lansmanı İçin Organizasyon Fikirleri” gibi listeler ve rehberler yayınlayabiliriz. Bu içerikler hem evlenecek çiftlerin hem de şirketlerin ilgisini çekecektir. Bursa SEO sadece teknik bir iş değil, aynı zamanda yaratıcılık da gerektiriyormuş.

Selamlar, biz Bursa’da düğün, nişan ve kurumsal etkinlikler düzenleyen bir firmayız. Yaptığımız işleri Instagram’da paylaşıyoruz ama web sitemiz biraz atıl kalmıştı. “Bursa düğün organizasyon firmaları” aramasında görünür olmak istiyoruz. Aklıma şöyle bir fikir geldi: Sitemizin blogunda “Bursa’daki En İyi 10 Kır Düğünü Mekanı”, “Şirket Lansmanı İçin Organizasyon Fikirleri” gibi listeler ve rehberler yayınlayabiliriz. Bu içerikler hem evlenecek çiftlerin hem de şirketlerin ilgisini çekecektir. Bursa SEO sadece teknik bir iş değil, aynı zamanda yaratıcılık da gerektiriyormuş.

Herkese merhaba. Biz Bursa ve çevre illerde ev ve fabrikalar için güneş paneli (GES) kurulumu yapıyoruz. Bu konu biraz teknik olduğu için müşterilerimizin çok fazla sorusu oluyor. Web sitemizi bir bilgi portalına dönüştürmeye karar verdik. “Güneş Paneli Devlet Teşvikleri”, “Ev için GES Kurulum Maliyeti”, “Bursa’nın Güneşlenme Süresi ve Enerji Verimliliği” gibi konularda detaylı yazılar hazırlıyoruz. İnsanlar bilgi ararken sitemize ulaştığında, uzmanlığımızı görüp bizden teklif alma olasılıkları artacaktır. Bu içerik odaklı bursa seo yaklaşımının, bizim sektör için en doğrusu olduğuna inanıyorum.

Herkese merhabalar, forumda dijital pazarlama konularını takip ediyorum. Ben Bursa’da peyzaj mimarlığı yapıyorum, özellikle Bademli ve Balat tarafında villa bahçeleri tasarlıyorum. Benim işim tamamen görsel. Yaptığım bahçelerin fotoğraflarını Instagram’a ve siteme yüklüyorum ama bu bana yeterince yeni müşteri getirmiyor. İnsanlar genelde ‘tavsiye’ ile geliyor. İnternetten ‘Bursa bahçe tasarımı’ diye aratan potansiyel müşterilere bir türlü ulaşamıyorum. Son zamanlarda anladım ki, sadece fotoğraf yüklemek yetmiyormuş. Siteme ‘Bursa için Kış Bahçesi Bakım İpuçları’ veya ‘Küçük Balkonlar İçin Peyzaj Fikirleri’ gibi yazılar eklemem gerekiyormuş. Bu Bursa SEO meselesi sadece anahtar kelime yazmaktan çok daha derinmiş. Aramızda benim gibi proje bazlı ve görsel odaklı iş yapıp da web sitesinden verim alan var mı? Blog yazmak gerçekten de varlıklı müşteri kitlesine ulaşmada etkili oluyor mu? Tecrübelerinizi merak ediyorum.

siteniz harika vermiş olduğunuz makaleler için teşekkür ederim sitenize sürekli gelmek istiyorum başarılarınızın devamını bekliyorum

siteniz muazzam sürekli böyle paylaşım yapmanızı rica ediyorum

Turkey private tours Stephanie W. – Bangladeş https://elite-pet.shop/?p=16819

disposable thc vapes with potent clean flavors

中職賽程粉絲必備的官方認證資訊平台,24小時不間斷提供官方中職賽程新聞、球員數據分析,以及專業的比賽預測。